Mochini oa granulator o sisinyehang ke sesebelisoa se sebetsang hantle haholo se sebelisetsoang ho bokella lisebelisoa tse fapaneng liindastering tse joalo ka meriana, lik'hemik'hale le phepelo ea lijo. Mochini ona o sebelisa ho sisinyeha ha mochini le moralo o ikhethileng oa kamore ea granulation ho fihlela granulation e nepahetseng le e ts'oanang. E na le litšobotsi tsa sebopeho se bonolo le se utloahalang, mokhoa o tsoetseng pele oa granulating le ho boloka matla. Mochine o loketse ho etsa li-granules tsa litlhaloso tse fapaneng lik'hemik'hale, lijo le liindasteri tse ling.

Mofuta oa mochini: Granulator

Sephetho (kg/h): 30

Matla: 110V / 220V

Boemo(L*W*H): 460x550x570mm

Boima ba 'mele (KG): 55

Matla (kW): 0.55

Liindasteri tse sebetsang: Setsi sa Tlhahiso, Lijo& Feme ea Beverage, Retail, Food

Mohlala |

YK-60 | YK-90 | YK-160 | YK-320 |

| Bokhoni (kg/h) | 20-25 |

50-100 |

200-300 | 300-600 |

| Boholo ka kakaretso (mm) | 530x400x530 |

460x750x840 |

1260x750x1150 |

1500x1000x1400 |

| Enjene (kw) | 0.37 |

0.75 |

3 | |

| Dia. Ea Barrel (mm) | 60 | 90 | 160 | 320 |

Leqhubu la Leqhubu (°) |

>360 | >360 | >360 | >360 |

Boima (kg) |

55 | 150 | 360 | 550 |

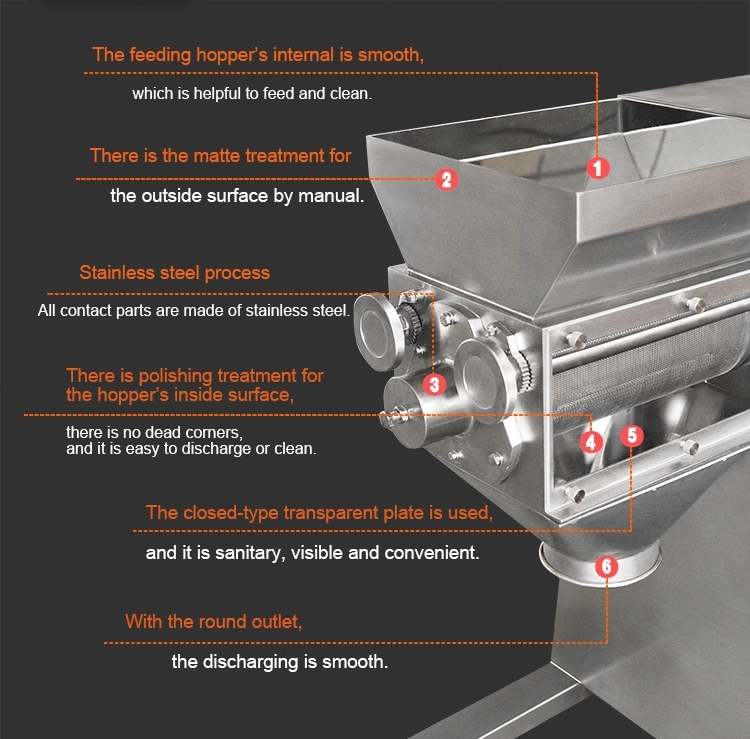

Lintlha tse ka sehloohong:

1. Sebetsa se Phahameng sa Granulation: Mochini o sisinyehang oa granulator o fetola ka nepo li-powders kapa likaroloana tse ntle ho li-granules tse ts'oanang ka ts'ebetso e phahameng, ho netefatsa boleng bo botle ba sehlahisoa.

2. Li-Parameters tse Fetohang tsa Granulation: Mochini ona o fana ka maemo a feto-fetohang a ho lokisa liparamente tsa granulation joalo ka matla a ho sisinyeha, amplitude, le nako ea ho fihlela litlhoko tse ikhethang tsa boholo ba granule le letsoalo.

3. Mokhoa o Bonolo oa Granulation: Ketso e bonolo ea ho thothomela ea mochini e fokotsa tlhahiso ea mocheso nakong ea granulation, e bolokang botšepehi ba lisebelisoa tse nang le kutloelo-bohloko kapa tse baballang mocheso.

4. Tekano e Ikamahanyang le Lintho: Mochini oa granulator o sisinyehang o loketse mefuta e mengata ea lisebelisoa, ho kenyeletsoa metsoako ea meriana, lik'hemik'hale tse ntle, li-additives tsa lijo tse phofshoana le manyolo a granulated.

5. Ts'ebetso e Bonolo le Tlhokomelo: Mochini o na le litaolo tse bonolo tsa basebelisi, tse lumellang basebelisi ho fetola litlhophiso habonolo. Ho phaella moo, mohaho oa eona o bonolo o tiisa ho hloekisa le ho hlokomeloa habonolo.

6. Moralo oa Compact le Phokotso ea Lerata: Mochini oa granulator o sisinyehang o etselitsoe ho nka sebaka se fokolang libakeng tsa tlhahiso, o etsa hore o tšoanelehe bakeng sa ts'ebetso e nyane le e kholo. Sistimi e kopaneng ea ho fokotsa lerata e netefatsa tikoloho ea ts'ebetso e khutsitseng.

Lisebelisoa:

Mochini oa granulator o sisinyehang o fumana lits'ebetso tse ngata liindastering tse fapaneng, ho kenyelletsa empa ha li felle feela ho:

- Indasteri ea Litlhare: Granulation ea metsoako ea meriana, joalo ka matlapa, li-capsules le li-granules bakeng sa mefuta ea litekanyetso tsa molomo.

- Indasteri ea lik'hemik'hale: Granulation ea phofo ea lik'hemik'hale, li-catalysts, li-pigments le lik'hemik'hale tse ling tse ntle.

- Indasteri ea Phetoho ea Lijo: Granulation ea li-additives tsa lijo, litlolo tse entsoeng ka phofo, le metsoako ea indasteri ea lijo le lino.

- Indasteri ea Temo: Granulation ea manyolo, ho netefatsa boholo bo nepahetseng ba likaroloana le ho lokolloa ha limatlafatsi tse laoloang.

Ikopanye le Rona

Ntho ea pele eo re e etsang ke ho kopana le bareki ba rona le ho buisana ka lipheo tsa bona morerong o tlang.

Nakong ea seboka sena, ikutloe u lokolohile ho fana ka maikutlo a hau le ho botsa lipotso tse ngata.