Model :HSR-60/100/180H/200H/200/250C/250/300H

Die roll revolution speed:0-6 rpm Stepless speed adjust

Machine output(capsules/hour ):6000-150000(8#OV)

Filling difference:±2%

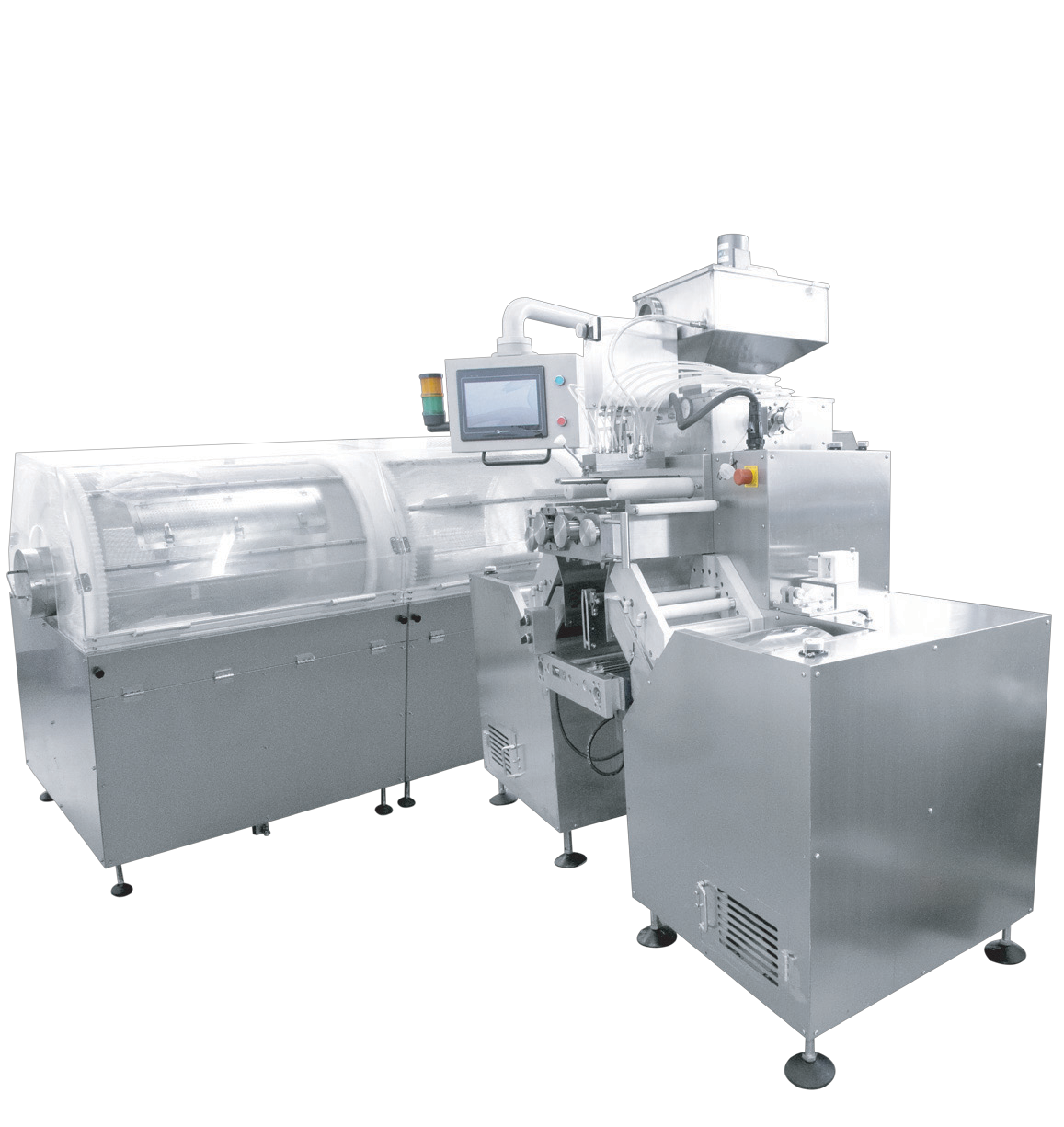

HSR-180H/200H/250H/300H series softgel production line is mass production equipment and suitable customers with different capacity requirements.The equipment has compact structure, easy operation, simple maintenance, stable performance, high production and low consumption. It is suitable for food,pharmaceutical , cosmetics,paintball and chemical industry.

HSR Encapsulation Machine

This is your team section. It’s a great space to tell your story and to describe who you are and what you do. If you're a business, talk about how you started and tell the story of your professional journey. People want to know the real you, so don't be afraid to share personal anecdotes. Explain your core values and how you, your organization, or your business stand out from the crowd.

New modular and standardized design:structure simple and stable, the spindle runs more stable.

Main machine drive system:No liquid lubricant required.

Materials supplying pump system:

Specially design for the extracts suspension sticky filling materials,wide range of applicable filling materials.

Injection Wedge temperature control:Double PID control to ensure rapid response and precise control of injection wedge temperature.

Gelatin film transmission:Full-range autonomous drive into the die roller,no sliding pull, no film deformation and perfect capsules shape.

Gelatin film linear conveying, no need to adjust, production stable.

Control type: Each system independent control, coordinated accordingly, easy to adjust.

Die roller Pressure type: Pneumatic constant voltage, digital display, stable and convenient.

Die roller adjustment: Free line aligning design, simplified operation to prevent operator’s error.

Injection wedge lifting type: Electric self-locking, safe and reliable.

Material supply pump: Free adjust design, easy install, prevent operator’s error,design of all rolling bearings to prolong service life.

Material supply pump direction guidance: spherical guide (numerical control machine tool technology)

Model |

Maximum Production Capacity (Count as 0.5g Oval Shape capsule ,capsules/hour) |

HSR-180H |

74520 |

| HSR-200H | 86400 |

| HSR-250H | 147000 |

HSR-300H |

178500 |

Full-automatic Gelatin Melting and Material Supply System

Full-automatic gelatin melting and material supply system is designed according to the actual situation of softgel production.It can realize to produce strictly according to the specified production process and reduce human intervention in production process to ensure consistency of gelatin and material in each batch.

1.Installation of the system is in conjunction with the project site,flexible and reliable.

2.Quantitative liquid flow meter installed in pipeline,on-line quantitative feeding reducing secondary pollution.

3.Independent weighing system ensures the stability of the whole system.

4.Process interlocking control to avoid misoperation leading to system failure

HSZJ Series Vacuum Stirring System

Hszj series vacuum stirring system is a kind of homogenizing equipment which consists of water (steam) bath type heating vacuum stirring tank, buffer tank and condensing tank. It is widely used in pharmaceutical, food and precise chemical industries.

PY Series Filling Material Preparation Tank

Py series filling material preparation tank is a kind of single layer stirring tank,the tank can bear certain negative pressure. The tank body is stainless steel and completely meets the GMP requirement.

Stainless Steel Colloid Mill

不锈钢胶体磨设备fine processing of fluid materials. It integrates the various properties of homogenizer, ball mill, three-roll mill, shearing machine, mixer and other machines.It has the function of superior superfine grinding, dispersive emulsification, homogenization, mixing,etc

HSGZ-3 Tumble Dryer

It is mainly used for shaping fixing drying of softgel capsules production line. Meanwhile,it could also be applied to granular materials dynamic drying in Pharmaceutical,Food and Chemical industries.

Main Features:

* Special Side-cut air blowing system makes the cages with the uniform air blow to fasten the drying speed.

* Precisely design of air blowing pipe guarantees none of any other particles entering into the pipe.

* Non-oil lubrication structure is adopted for the rotating cage of the dryer to avoid the pollution of lubricant

thoroughly.The whole machine will be kept clean during the production process.

* The cages adopts the latest structure design to guarantee the dependability of material conveying in multi-cages operation.

* The precise design and manufacturing guarantee that no influence to other cages running when disassemble any of the cage from the multi-cages.

* The loading tray is set up in each cage to make the workshop floor tidy and clean and also reduce the waste of finished products.

* Each dryer can be separately moved and fast combing, it shortened the machine’s maintenance time and reduced the operator's labor strength.

Vacuum Stirring Tank

Main features:

·完全由不锈钢和满足requirements of GMP.

· The barrel lid is equipped with gas connector, pressure gauge and safety valve,also equipped with exhaust outlet and high position materials outlet, it makes the operation more safe and reliable.

· The barrel body is a three-layer structure.There is a heating water jacket between the inner layer and the middle layer, and between the middle layer and the outer layer is high-efficiency insulation materials. The barrel lid is a double-layer structure filling with high-efficiency insulation material, which has high heat transfer efficiency and does not affect the environmental temperature.

· The barrel is especially suitable for small amount of gelatin melting in experiment.It is both used for melting and storage of gelatin during the

Water Chiller

The water chiller controls compressor start-up and shutdown through automatic temperature regulation and the temperature of coolant can be controlled.It is the auxiliary equipment for the softgel encapsulation machine and blisterpacking machineetc

HSXW-2 Capsule Washing Machine

SXW-2 Capsule Washing Machine is a fully automatic capsule or drop pill washing machine with function of jet swirl washing, spraying and air drying.The washing is completely and efficient. After washing, the surface of the capsules or drop pill is free from any cleaning solution. It's the ideal equipment for cleaning soft capsules or drop pills.

Common Softgel Shapes&Filling Quantity

|

ROUND |

|||||||||

NO. |

1.5 |

2 |

3 |

6 |

7 |

8 |

10 |

36 |

40 |

|

MINIMS |

1.5 |

2 |

3 |

6 |

7 |

8 |

10 |

36 |

40 |

|

| mL |

0.092 |

0 .123 |

0.185 |

0.37 |

0.431 |

0.493 |

0.616 |

2.218 |

2.464 |

|

|

OBLONG |

|||||||||

| NO |

4 |

5 |

6 |

8 |

10 |

11 |

14 |

16 |

20 |

|

| MINIMS |

4 |

5 |

6 |

8 |

10 |

11 |

14 |

16 |

20 |

|

| mL |

0.246 |

0.308 |

0.37 |

0.493 |

0.616 |

0.678 |

0.863 |

0.986 |

1.232 |

|

|

OVAL |

|||||||||

| NO | 1.5 |

2 |

3 |

4 |

5 |

6 |

8 |

10 |

32 |

|

| MINIMS | 1.5 |

2 |

3 |

4 |

5 |

6 |

8 |

10 |

32 |

|

| mL | 0.092 |

0.123 |

0.185 |

0.246 |

0.308 |

0.37 |

0.493 |

0.616 |

1.972 |

|

|

TUBE |

|||||||||

| NO | 5 |

5.5 |

6 |

8 |

9 |

9.5 |

10 |

18 |

20 |

|

| MINIMS | 5 |

5.5 |

6 |

8 |

9 |

9.5 |

10 |

18 |

20 |

|

| mL | 0.308 |

0.339 |

0.37 |

0.493 |

0.555 |

0.585 |

0.616 |

1.109 |

1.232 |

|

|

DROP |

|||||||||

| NO | 5 |

6 |

8 |

10 |

12 |

15 |

20 |

24.5 |

30 |

|

| MINIMS | 5 |

6 |

8 |

10 |

12 |

15 |

20 |

24.5 |

30 |

|

| mL | 0.308 |

0.37 |

0.493 |

0.616 |

0.739 |

0.942 |

1.232 |

1.509 |

1.848 |

|

|

CALABSH |

|||||||||

| NO | 4 |

5 |

5.5 |

6 |

6.5 |

8 |

10 |

12 |

15 |

|

| MINIMS | 4 |

5 |

5.5 |

6 |

6.5 |

8 |

10 |

12 |

15 |

|

| mL | 0.246 |

0.308 |

0.339 |

0.37 |

0.4 |

0.439 |

0.616 |

0.739 |

0.924 |

|

|

GOLDFISH |

|||||||||

| NO | 10 |

12 |

14 |

15 |

16 |

18 |

19 |

20 |

25 |

|

| MINIMS | 10 |

12 |

14 |

15 |

16 |

18 |

19 |

20 |

25 |

|

| mL | 0.616 |

0.739 |

0.863 |

0.924 |

0.986 |

1.109 |

1.17 |

1.232 |

1.54 |

|

|

FLAGON |

|||||||||

| NO | 6 |

7 |

7.5 |

8 |

8.5 |

9 |

10 |

12 |

15 |

|

| MINIMS | 6 |

7 |

7.5 |

8 |

8.5 |

9 |

10 |

12 |

15 |

|

| mL | 0.37 |

0.431 |

0.462 |

0.493 |

0.524 |

0.555 |

0.616 |

0.739 |

0.924 |

|

|

FISH |

|||||||||

| NO | 4 |

5 |

6 |

7 |

7.5 |

8 |

9 |

10 |

12 |

|

| MINIMS | 4 |

5 |

6 |

7 |

7.5 |

8 |

9 |

10 |

12 |

|

| mL | 0.246 |

0.308 |

0.37 |

0.431 |

0.462 |

0.493 |

0.555 |

0.616 |

0.739 |

|

|

AUBBRGINE |

|||||||||

| NO | 5 |

6 |

6.5 |

7.5 |

8 |

9 |

10 |

12 |

39 |

|

| MINIMS | 5 |

6 |

6.5 |

7.5 |

8 |

9 |

10 |

12 |

39 |

|

| mL | 0.308 |

0.37 |

0.4 |

0.462 |

0.493 |

0.555 |

0.616 |

00.739 |

2.402 |

|

Don't choose the expensive one,

just choose the right one

SINOPEDadheres to the concept of "comfortable service, safe use, quality assurance" to serve every customer!

SINOPEDhas a special after-sale service team to offer Technical Support and Maintenance Train in this machine whole life

24month of the Warranty period, since the date when the machine arrives

24hours Online Consultant Service .

SINOPEDhas an after-sale service center in theUnited States,Brasil,Germany,Turkey,Thailand,Pakistan.

Engineer able to check on-site within 48hours

Special after-sale team for overseas installation, debugging, and technical support

Machine Working Theory. Machine Composition. Basic operation. Common Maintenance. Change Mould.